Applying digital twins to accelerate equipment diagnostics

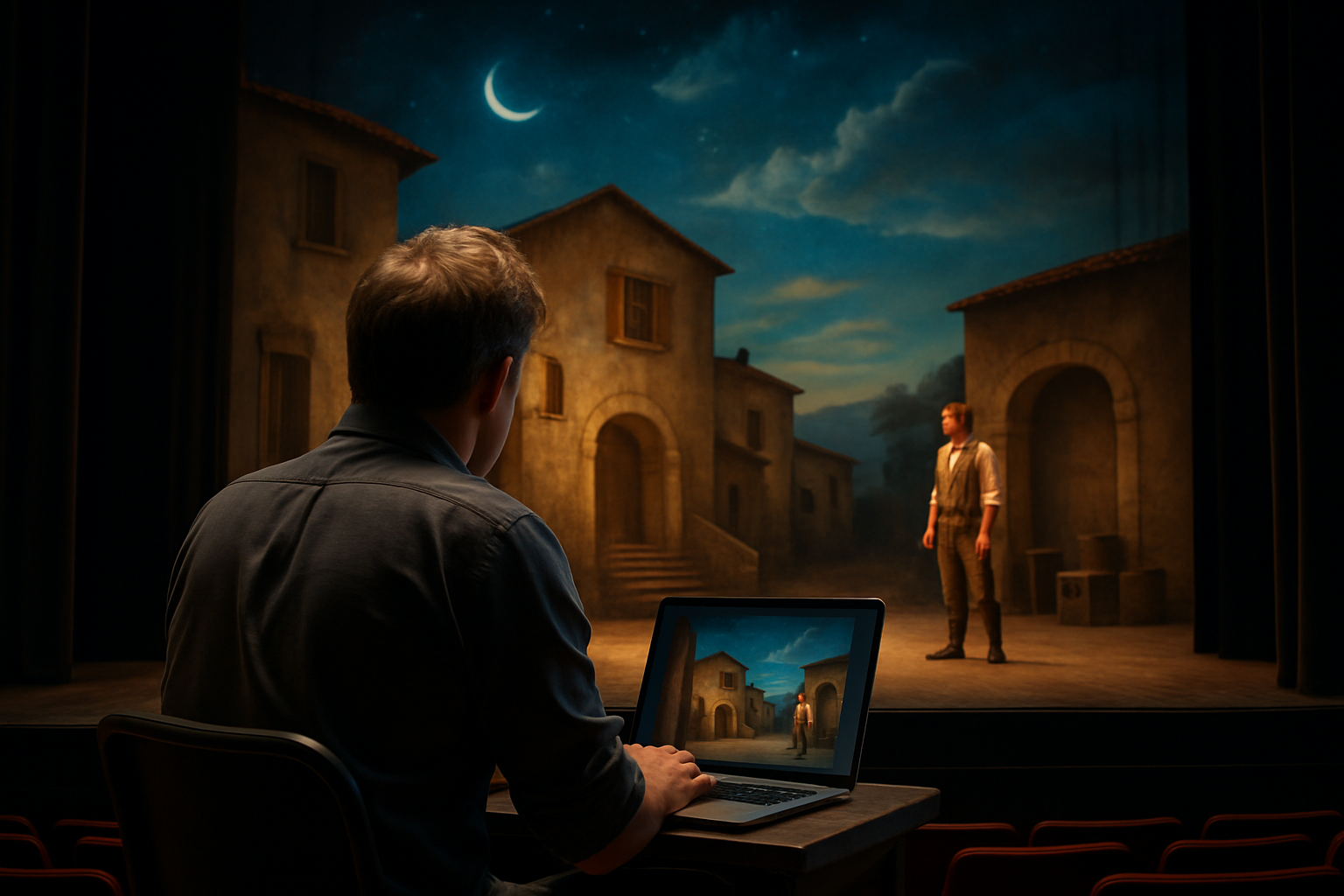

Digital twins create virtual replicas of physical equipment, combining sensor data, models, and analytics to make diagnostics faster and more precise. When applied across assets, these replicas help detect faults earlier, reproduce issues virtually, and prioritize maintenance based on risk. This article explains practical ways organizations use digital twins to speed equipment diagnostics while addressing integration and operational concerns.

How do digital twins use IoT and analytics?

Digital twins rely on IoT to collect real-time telemetry—temperatures, vibrations, pressures, and other sensor signals—from equipment. That live stream feeds analytics engines which compare observed performance to the digital model’s expected behavior, surfacing deviations that indicate incipient faults. By correlating time-series data with physics-based or machine-learning models, teams can detect patterns that were previously invisible in siloed datasets, improving diagnostic accuracy and reducing mean time to detect.

In practice, integrating IoT requires attention to data quality, latency, and edge processing. Local services or on-site gateways often preprocess signals so the twin receives normalized, reliable input for analytics and diagnostic routines.

Can digital twins improve maintenance and diagnostics?

Digital twins enable condition-based and predictive maintenance strategies by simulating failure modes and estimating remaining useful life. Diagnostics are accelerated because the twin can reproduce fault scenarios in a safe virtual environment: engineers test hypotheses without stopping equipment or risking production. This reduces reliance on trial-and-error troubleshooting and helps prioritize interventions where they will have the greatest impact on uptime and safety.

Maintenance teams can thus move from scheduled or reactive approaches to targeted repairs based on diagnostic confidence scores produced by twin-driven analytics.

What role do automation and robotics play?

Automation systems and robotics extend the reach of digital-twin-driven diagnostics into physical action. Once a twin identifies a localized issue, automated control systems can execute safe, predefined tests or adjust operating parameters to validate the diagnosis. Robotics can carry out inspections or swap modular components based on diagnostic directives, minimizing human exposure to hazardous environments.

Coordinating automation with the twin’s insights requires reliable communications and standardized interfaces between control systems, robotics platforms, and the digital model.

How can digital twins support logistics and supplychain operations?

Diagnostics insights from equipment twins feed into logistics and supplychain planning by forecasting spare-parts needs and scheduling deliveries ahead of failures. When a twin signals an increased likelihood of a specific component fault, procurement and logistics teams can preposition parts or allocate mobile repair crews, shortening repair lead times and avoiding production bottlenecks.

This alignment between diagnostics and supplychain reduces emergency shipments, improves inventory turnover, and supports smoother service workflows across distributed assets.

How are cybersecurity and digitization managed for diagnostic twins?

Digitization increases attack surface area; therefore cybersecurity must be integral to twin deployments. Secure device authentication, encrypted telemetry, role-based access to diagnostic models, and tamper-evident logging help ensure the integrity of diagnostic outputs. Governance policies should define who can change model parameters, run simulations, or act on diagnostic recommendations to prevent unauthorized interventions.

Robust incident response and regular vulnerability assessments protect both the physical equipment and its virtual counterpart from malicious manipulation that could lead to false diagnostics or unsafe control actions.

How do digital twins contribute to efficiency, resilience, and sustainability?

By accelerating diagnostics and enabling targeted interventions, digital twins reduce downtime and wasted energy, improving overall equipment efficiency. Faster diagnostics contribute to operational resilience by shortening recovery times after disruptions and reducing the likelihood of cascading failures. From a sustainability perspective, optimized maintenance lengthens asset lifetimes and reduces unnecessary part replacements and logistics emissions.

Organizations should track metrics—diagnostic lead time, repair frequency, energy usage—to quantify efficiency and sustainability gains, and continuously refine twin models as more diagnostic data accumulates.

Conclusion

Applying digital twins to equipment diagnostics links real-time IoT data with analytics and virtual modeling to detect faults earlier, validate diagnoses virtually, and coordinate automated responses and logistics. When combined with strong cybersecurity, thoughtful digitization practices, and alignment with maintenance and supplychain processes, digital twins can accelerate diagnostics while enhancing efficiency, resilience, and sustainability across industrial fleets.